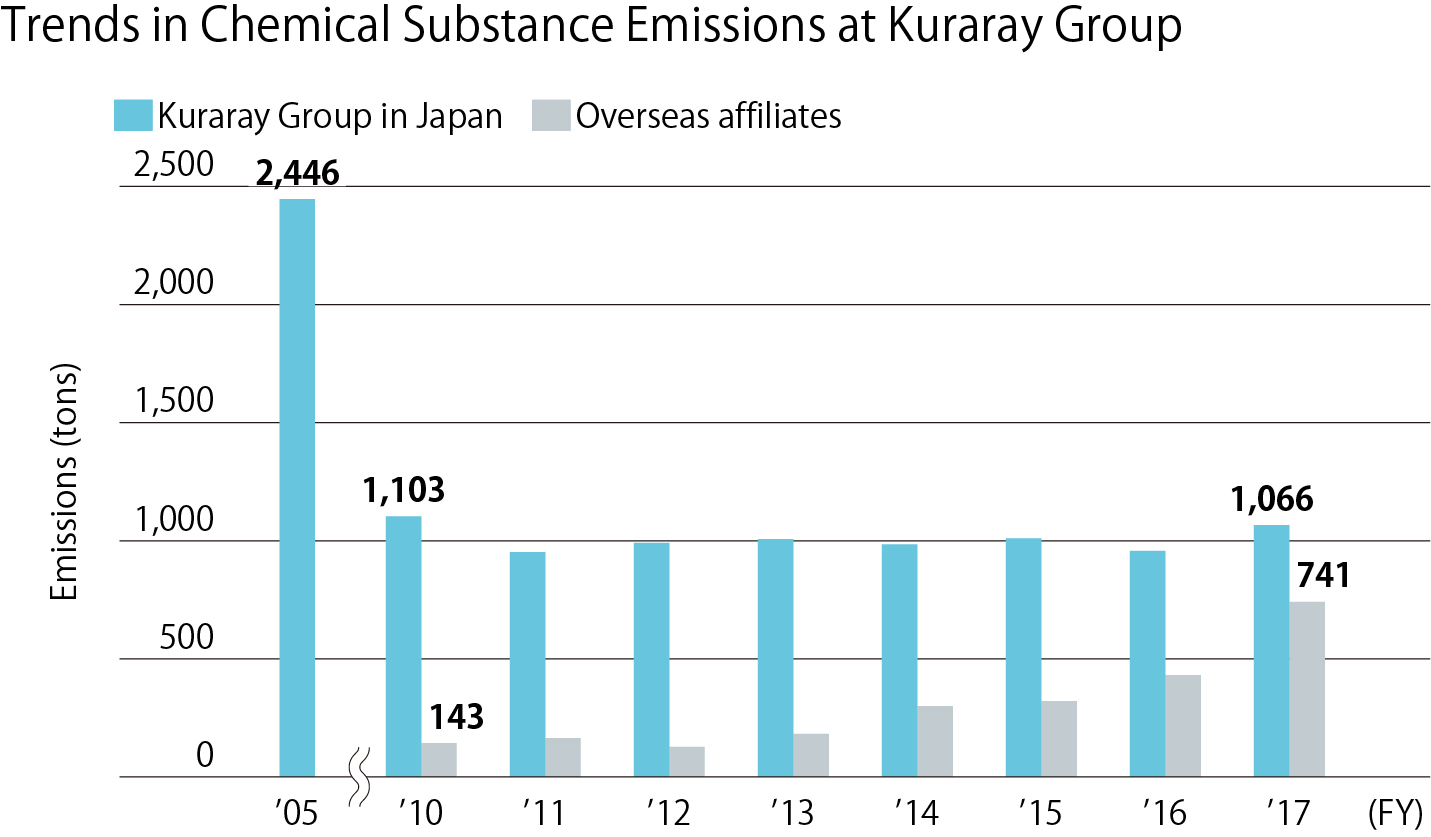

In fiscal 2017, emissions of PRTR substances* of the entire Kuraray Group in Japan totaled 1,066 tons (982 tons into the atmosphere and 84 tons into water areas). The environmental efficiency of the Kuraray Group in Japan improved by 20.1% compared with fiscal 2010. Even though the production volume has increased, we took measures not to increase emissions such as by changing the production process from an organic solvent system to a water system.

The emissions of the Kuraray’s affiliates outside Japan show an increasing trend because we incorporated new business through M&As and the capacity utilization of new production sites rose. However we are working to control emissions while complying with the strict regulations for chemical substances of each country. Emissions of the Kuraray's affiliates outside Japan totaled 741 tons in fiscal 2017.

* Substances subject to the PRTR Act and substances designated by the Japan Chemical Industry Association