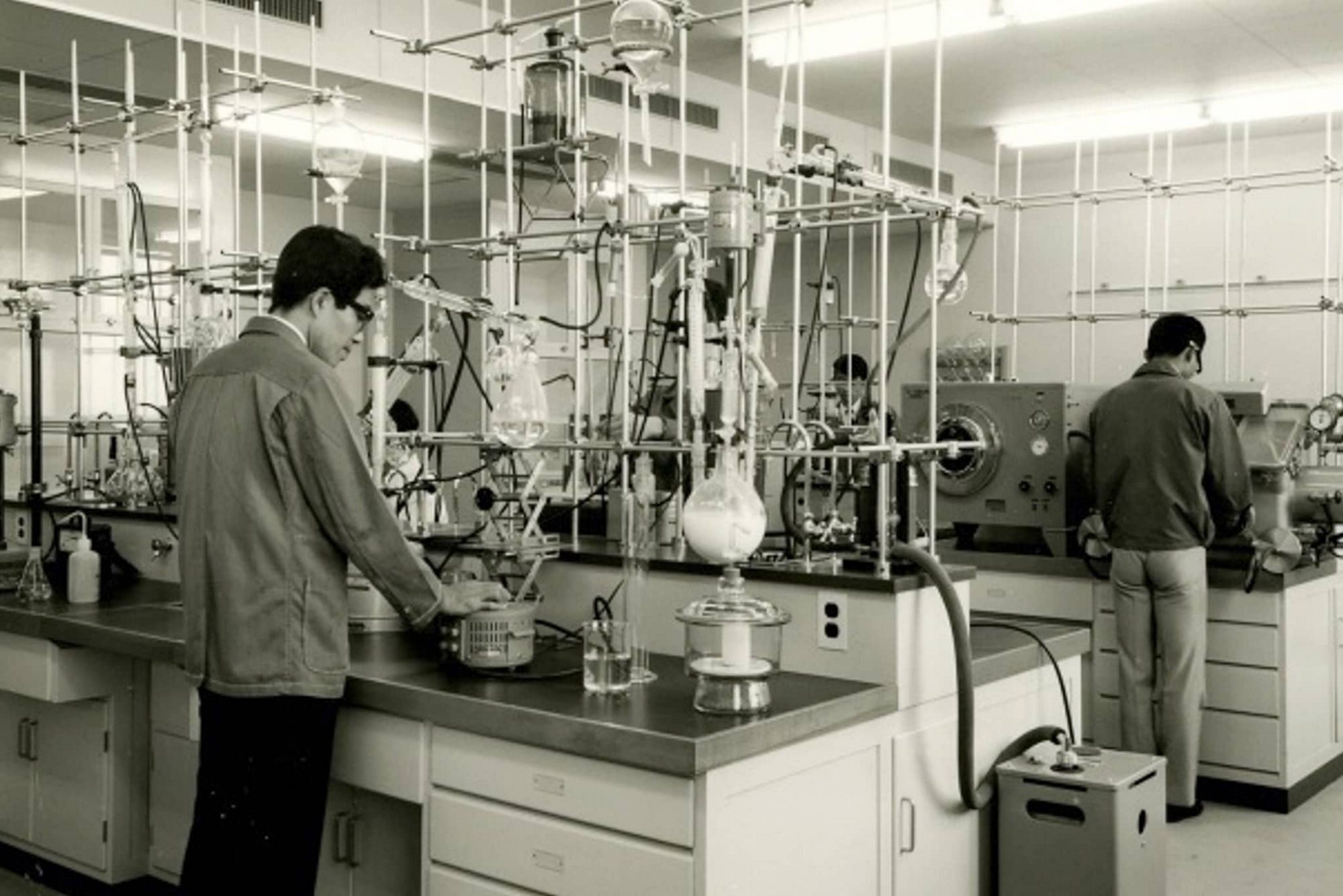

Research and Development

The Kuraray Group, in alignment with its management strategy, is committed to the creation, development, and promotion of new businesses from a mid- to long-term perspective, as well as the strengthening and expansion of existing businesses. Centered around the Research and Development Division, we are committed to providing high-quality products that benefit daily life, society, and industry through our research and development efforts.