Kuraray Confirms the Robustness of High-Voltage Tracking Resistance Afforded by GENESTAR™ through Third-Party Assessments

Kuraray Co., Ltd. (Headquarters: Chiyoda-ku, Tokyo; President: Hitoshi Kawahara; hereinafter “Kuraray”) hereby announces that it confirmed the robustness of high-voltage tracking resistance afforded by the heat-resistant polyamide resin GENESTAR™. Testing was conducted to a maximum voltage of 900 volts and was carried out in accordance with the latest standard for tracking resistance, the UL 2597 Outline of Investigation for Test Method for Materials for Use in Transportation Applications: Surface Tracking Test (STT) Method published in May 2025 by UL Standards & Engagement, a non-profit organization that formulates international safety standards.

1. Background

In recent years, the use of high-voltage power sources for electric vehicles (EVs) has grown, with an 800-volt system commercialized in 2020. There are even a number of new systems exceeding 1000 volts on the verge of release. The higher the voltage, the more robust the electrical insulation provided by the resin materials used needs to be. In fact, having robust tracking resistance is now an important factor in evaluating materials of this kind.

Previous tracking resistance tests have been conducted in compliance with ASTM D3638 and IEC 60112, which are limited to a maximum test voltage of 600 volts. As a result, there is a gap between conventional testing environments and actual usage conditions, which often involve much higher voltages.

Until now, Kuraray used its own methods to assess the tracking resistance of GENESTAR™ in its efforts to confirm that a tracking phenomenon* would not occur even when the material is subjected to 900 volts, with voltages used in testing ranging from 600 to 1000 volts. However, UL Standards & Engagement published the latest UL 2597 standard in May 2025, making it possible to conduct standardized third-party evaluations in the voltage range of 600 to 900 volts.

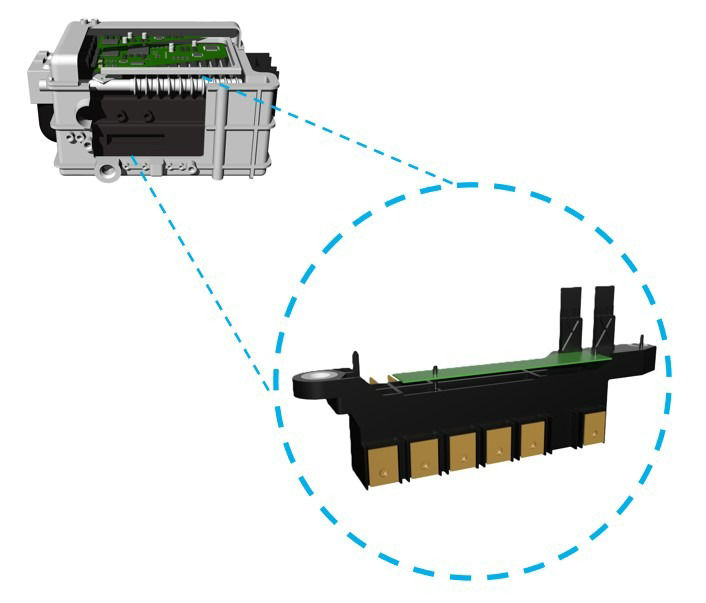

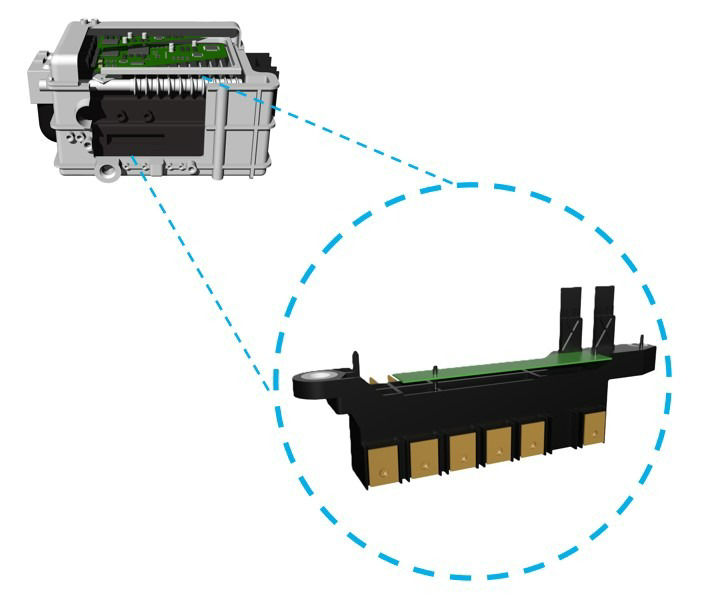

Examples of intended applications

2. Results of GENESTAR™ Based on Measurements in Compliance with the UL 2597 Standard

The surface tracking tests in accordance with the UL 2597 standard were conducted by UL Solutions, to assess the tracking resistance of GENESTAR™.

Through these tests, we confirmed that GP2450NH-2 BLACK, which is a halogen-free flame retardant grade (certified to UL 94 V-0), would not allow the tracking phenomenon to occur even when subjected to 900 volts, the maximum voltage prescribed under the UL 2597 standard. We were thus able to confirm the robustness of tracking resistance afforded by GENESTAR™ in a high-voltage testing environment, a property that has previously not been readily assessable using conventional testing standards.

Looking ahead, Kuraray will continue to develop its proprietary material GENESTAR™. This will enable the Company to provide solutions to support the creation of compact, high-performance vehicle-mounted components for high-voltage EVs as well as the safety of the EVs as automotive technologies further evolve.

* Tracking is a phenomenon in which repeated micro-discharges on the surface of an insulating material cause local carbonization and the formation of conductive paths. In high-voltage environments, tracking can cause insulation breakdown or fire. Accordingly, tracking resistance is considered an important indicator in the safety evaluation of resin materials.

■About GENESTAR™

・GENESTAR™, a heat-resistant polyamide resin developed in-house from raw material monomers, is the first of its kind in the world and is a proprietary material that we commercialized in 1999. It has such features as heat resistance, chemical resistance, low water absorbency, electrical insulation properties, and wear resistance. It has the particular advantage of being less prone to blistering problems with SMT connectors and is being increasingly used in electrical and electronic products.

・In addition to electrical and electronic applications such as connectors for smartphones and computers, and LED reflective material applications, it is also increasingly being used in housings and gears for cooling system parts in the automobile industry, where the need for weight reduction is growing. Furthermore, it has been increasingly utilized in automotive electrical parts in recent years.

・To handle expanding global demand and establish a stable supply system, the new plant in Thailand, which began operations in 2023, is conducting integrated manufacturing from monomers to polymers. With the new plant in Thailand commencing operations, we are now able to supply an annual total of 26,000 tons of polymer globally.

■About UL Standards & Engagement

UL Standards & Engagement is a nonprofit standards development and advocacy organization that translates data from safety science into practical, action-oriented safety standards. It convenes experts worldwide and serves as a vital resource for regulators and policymakers. As a part of its public outreach activities, UL Standards & Engagement shares knowledge, advances standards-related safety policy partnerships and advocates for standards and regulations that result in positive safety changes.

Image download service for the news media

We provide the ability to download images by clicking on them exclusively to the news media.