Overview

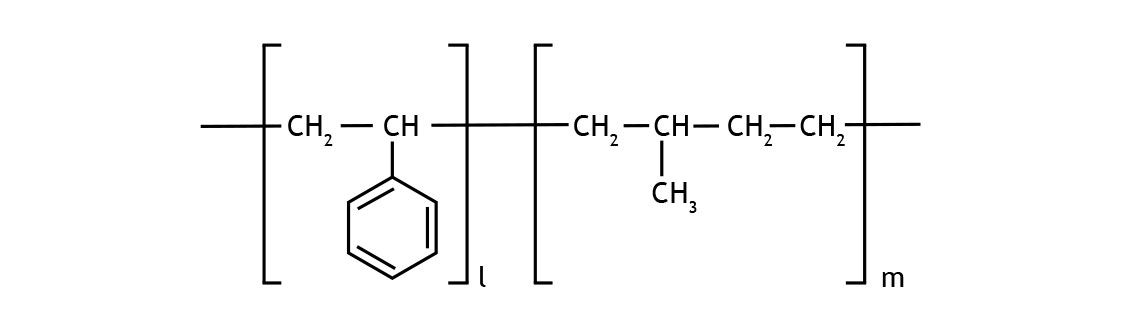

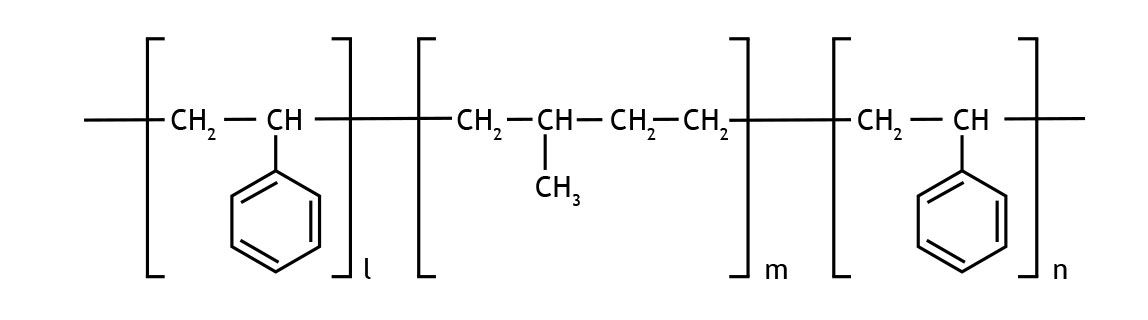

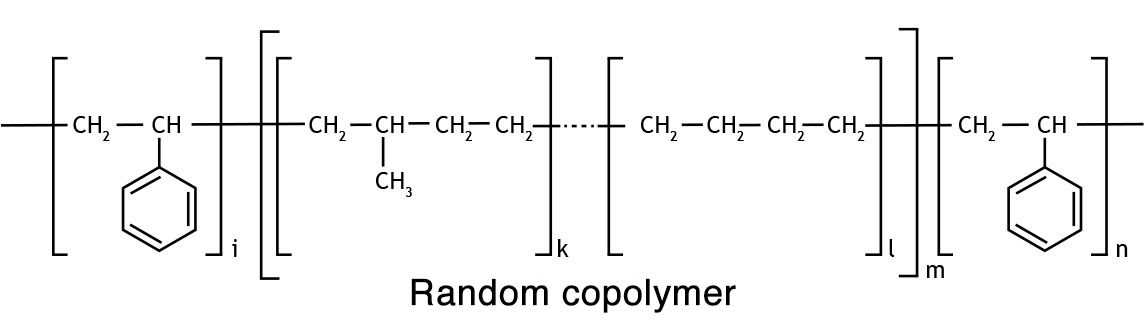

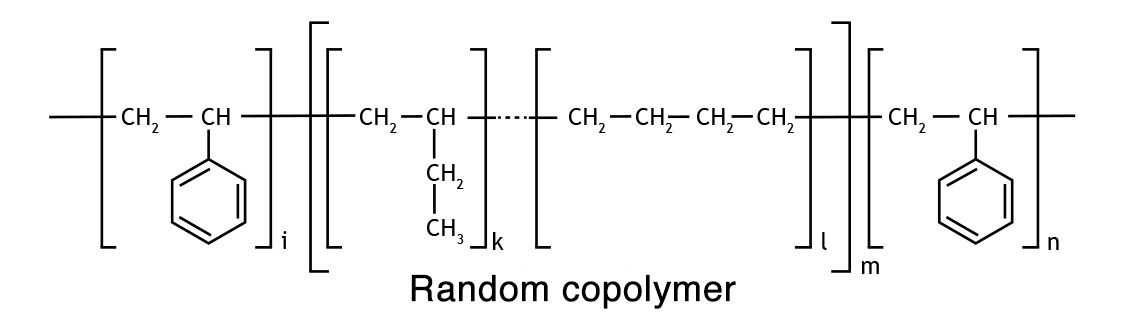

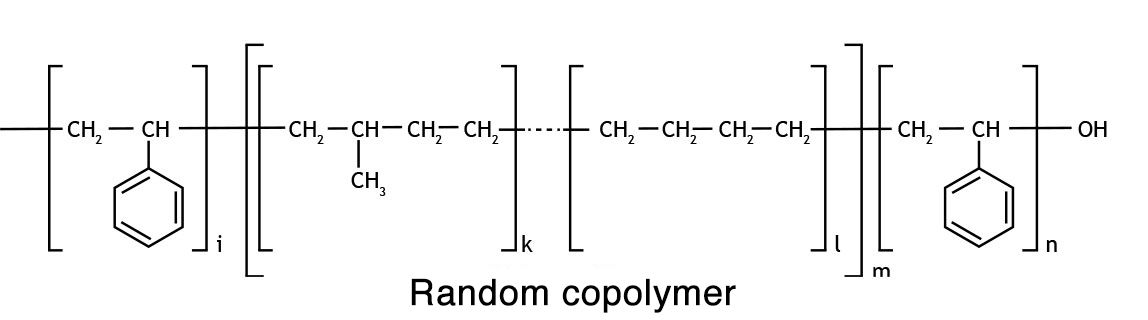

SEPTON™ is a styrenic thermoplastic elastomer developed by Kuraray. It is a block copolymer that consists of styrene-based hard-blocks and a diene soft block. SEPTON™ is used in a variety of TPE compounds. SEPTON™ can be processed in a wide variety of forms, including consumer goods, soft touch grips and automotive components.

For years, SEPTON™ has been setting benchmarks and transforming our perception of quality. SEPTON™ ignites innovation, consistently surpasses industry standards, and has become a staple in diverse domains.

Further information about SEPTON™