Developed Blister-Resistant Grade of GENESTAR™ Heat-Resistant Polyamide Resin Significantly Reduces Rate of Blister Occurrence and Enhances Productivity of Automotive Electrical Components

Kuraray Co., Ltd. (Headquarters: Chiyoda-ku, Tokyo; President: Hitoshi Kawahara) announces the development of a blister-resistant grade of GENESTAR™ heat-resistant polyamide resin that significantly reduces rate of blister occurrence (blister formation on the surface of molded products due to heating) for automotive connectors.

1.Background of Development

・With the shift to surface mounting technology (SMT) in automotive components, we have expanded the use of GENESTAR™ in automotive SMT connectors that work for reflow* processes, centering on the enhanced GN series of GENESTAR™. The conventional grade of this product is also less prone to blistering, but automotive connectors are larger and thicker than connectors for consumer use, and increasingly severe SMT conditions become required further improvements in blister resistance.

・In response to customer feedback, we have conducted research and development over several years, clarified the detailed mechanisms behind blistering, and developed a blister-resistant grade of product using over 20,000 evaluations and Kuraray's proprietary compounding technology.

*Reflow: A method of attaching components to printed circuit boards by printing solder paste (flux is added to solder powder to give it an appropriate viscosity), placing the components on top of the paste, and heating it to melt the solder.

2.Features of Blister-Resistant Grade of GENESTAR™

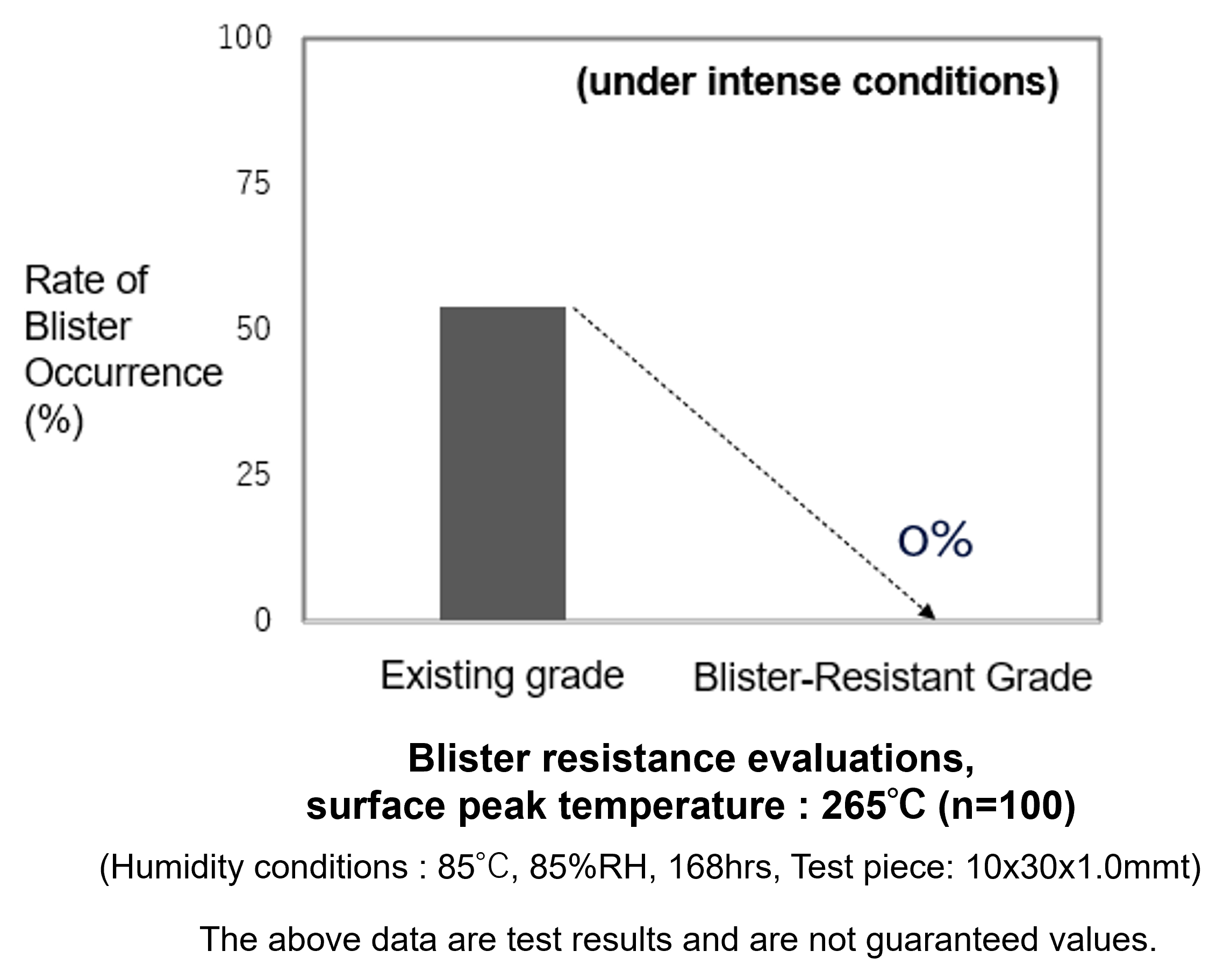

・The blister occurrence rate in SMT connectors has been significantly reduced* compared to the conventional grade.

・This has an excellent balance of strength and moldability required for automotive SMT connectors, and has obtained various UL certifications including flame retardant standard UL94 V-0.

・Because of its good color development, it works for automotive connectors that require high visibility. It can also match color products, including RAL colors, the German standard color chart.

・Another application is for industrial connectors used in harsh environments other than automobiles.

・Its excellent blister resistance improves the productivity of automotive electronic components and helps reduce costs.

・By improving reflow temperature and design freedom, this product helps realize safe, secure, and highly functional mobility.

*This data was tested under intense conditions where blistering may occur in the existing grade. The results are based on Kuraray’s proprietary testing system and do not guarantee the rate of blister occurrence for customers.

3.About GENESTAR™

・GENESTAR™ is a heat-resistant polyamide resin developed in-house from raw material monomers, is the first of its kind in the world, and is our proprietary material that we commercialized in 1999. It has features such as heat resistance, chemical resistance, low water absorbency, electrical insulation, and wear resistance. It has the particular advantage of being less prone to blistering problems with SMT connectors, and has been increasingly used in electrical and electronic products.

・In addition to electrical and electronic applications such as connectors for smartphones and computers, and LED reflective material applications, it is also increasingly being used in housings and gears for cooling system parts in the automobile industry, where the need for weight reduction is growing. Furthermore, it has been increasingly utilized in automotive electrical parts in recent years.

・To handle expanding demand and establish a global supply system, the new plant in Thailand, which began operations in 2023, is conducting integrated manufacturing from monomers to polymers. With the new plant in Thailand commencing operations, we are now able to supply an annual total of 26,000 tons of polymer globally.