News

Kuraray Co., Ltd. (Headquarters: Tokyo; President: Fumio Ito; hereafter "Kuraray"), has developed and initiated sales of two new VECSTAR liquid crystalline polymer products: CT-Z film with excellent heat resistance and FB film with superior optical reflectivity.

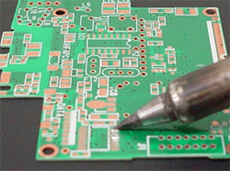

VECSTAR is a liquid crystalline polymer film developed by Kuraray using its proprietary film-forming technology. VECSTAR has superior electrical and high-frequency properties and heat-resistance as well as dimensional stability. Moreover, because of its low-moisture absorbency, it was primary developed as an insulating film for use in printed circuit boards (PCBs), especially high-speed PCBs. Recently, PCB development has advanced to higher frequencies, which enable high-capacity and high-speed processing owing to increases in the transmission speed of electronic data in areas such as PCs and digital cameras.

Not only do these two newly developed VECSTAR products offer higher frequency capabilities, they also provide higher heat resistance and optical reflectivity than existing products.

1. CT-Z Film

CT-Z film has the highest level of heat resistance among commercially available liquid crystalline polymer films. Because this new film features high-frequency electrical properties, it is the material best-suited for insulating flexible PCBs and multilayered PCBs. In addition, the excellent heat resistance of CT-Z film enables the hand soldering of PCBs using high-temperature soldering iron, a capability that has been difficult for existing products to achieve, and is expected open the way for additional applications.

2. FB Film

FB film has superior optical reflectivity. While possessing a heat resistance compatible with auto-soldering processes that utilize lead-free solder, it also provides the highest level of optical reflectivity among commercially available liquid crystalline polymer films. Moreover, since FB film's optical reflectivity deterioration due to heat is miniscule, Kuraray will market it as a material best suited for white LED PCB applications.

Furthermore, Kuraray plans to introduce its CT-Z and FB films at the Advanced Electronic Materials Expo (Jan. 20-22, 2010) to be held at Tokyo's Big Sight and (Booth No. East 24-002).

Comparison of CT-Z Film Properties with Those of the Existing VECSTAR CT-V Film

| CT-Z Film (Newly developed product) | CT-V Film (Existing product) | Comments | |

|---|---|---|---|

| Heat-resistance (50μm) ・ Heat-resistance properties required for hand-soldering processes (℃) (Soldering iron preset temperature) ・ Solder float heat-resistance (℃) | 380 350 | 350 320 | Kuraray method, 10 seconds JIS method, 60 seconds |

- * The above data are representative and not guaranteed values

CT-Z Film Features and Projected Applications

[Features]

- Retains the outstanding properties of the VECSTAR series

- Excellent heat resistance enables hand soldering and repair using a high-temperature soldering iron

- Best suited for use as insulating material (core material) for multilayered PCBs made from all-liquid crystalline polymer film in combination with VECTOR series low-melting-point film

[Projected Applications]

- High-frequency and high-speed transmission PCBs, flexible PCBs and multilayered PCBs used in PCs, servers, mobile phones, information home appliances and other products

Comparison of FB Film Properties with Those of the Existing VECSTAR Product

| FB Film (Newly developed product) | CT-S Film (Existing product) | Comments | |

|---|---|---|---|

| Optical reflectivity (50μm) ・ Condition (%) ・ After 150℃x1000 hours (%) ・ After 200℃x4 hours (%) | 80 80 80 | 70 70 70 | Wavelength: Measured 470nm |

| Heat-resistance (50μm) ・ Heat-resistance properties required for hand-soldering processes (℃) (Soldering iron preset temperature) ・ Solder float heat-resistance (℃) | 315 300 | 320 290 | Kuraray method, 10 seconds JIS method, 60 seconds |

- * The above data are representative and not guaranteed values

FB Film Features and Projected Applications

[Features]

- Retains the outstanding properties of the VECSTAR series

- Superior optical reflectivity

- Miniscule optical reflectivity deterioration due to heat

- Compatible with auto-soldering processes that utilize lead-free solder

[Projected Applications]

- White LED PCBs

- High-frequency and high-speed transmission PCBs, especially flexible PCBs, used in PCs, servers, mobile phones, information home appliances and other products