News

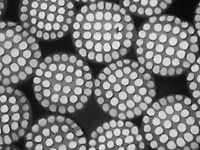

water soluble sea-island fiber

water soluble sea-island fiber

(Correction, Jan 5, 2006)

Kuraray Co., Ltd. (Headquarters: Chiyoda-ku, Tokyo; President: Yasuaki Wakui) announces the development and subsequent marketing of the TIRRENINA brand of next-generation, eco-friendly man-made leather, which combines the appearance and texture of natural leather with the superior functionality unique to man-made leather.

Amid heightening concern surrounding environmental issues, Kuraray introduced an innovative new process that does not utilize organic solvents in the production of TIRRENINA , succeeding in significantly reducing emission volume of organic solvents. In addition, Kuraray overcame the stiff texture often seen in water-based man-made leathers made with inorganic solvents, employing newly developed production processes and ultra-fine fibers to give TIRRENINA a texture, fullness and attractive appearance close to that of natural leather.

This year marks Kuraray's 40th year as the pioneer and top manufacturer of man-made leather, beginning with the study of natural leather and sales launch of CLARINO in 1965, a cutting edge material at that time. Kuraray's man-made leathers have received high marks and support in a variety of markets. CLARINO men's shoes gained notice when the "duck" television commercial advertising the shoes became the talk of the times. CLARINO schoolbags are loved by the many fans they have won over many years. AMARETTA is a variety of man-made leather with the look of high-grade suede, and is used in a variety of fields including apparel, interior and bags. Other man-made leathers include FLORISSIMO, a pressed soft material, and PARCASSIO, which incorporates some of the processes used on natural leather.

Kuraray has positioned TIRRENINA as next-generation, eco-friendly man-made leather, and will work to introduce this innovative new product on a global scale. We will continue to make advances in technologies related to fibers, nonwoven fabrics and finishing processes, and to provide highly original new materials with a pervasive presence in everyday life through wide applications in shoes, bags, sporting goods, apparel, interior and car seats.

Development Concept for TIRRENINA

- 1. Eco-friendly man-made leather made possible through innovative processes.

- 2. Combines the elegance and texture of natural leather with the functionality unique to man-made leather.

TIRRENINA Brand Eco- Friendly Man-Made Leather

1. Material Characteristics

- (1) Lineup includes raised type (brushed nubuck, suede, long hair) and pressed type

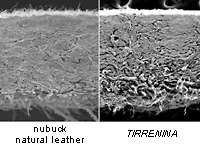

- (2) Texture and fullness close to natural leather through high-dense fiber structure

- (3) Balanced pliability both lengthwise and horizontally

- (4) Lineup includes type completely free of solvents

- Raised type

-

- (1) Diverse lineup of raised materials from brushed tone to velour (shaggy appearance)

- (2) Luxurious and colorful with a fluffy touch

- Pressed type

-

- (1) Luxurious and on-par with quality of natural leather in terms of fullness, roundness, pliability, touch and natural looking wrinkles and creases

- (2) Diverse variations for use in a broad array of applications

- Applications for men's and women's shoes granted with patent for heat setting.

- Sports shoe variety boasts superior abrasion resistance

- Applications for interior and car seats granted patents for high-level durability

- (3) A portion of materials granted patents for excellent moisture and air permeability

2. Technological Characteristics

| Textile | Kuraray's original water-soluble sea-island textile: Newly developed processes

|

|---|---|

| Resin | Water-based polyurethane emulsion and others |

| Substrate | Fibers and resins mentioned above intertwined in a three dimensional ultra-fine unwoven fabric; newly developed processes |

| Raised layer | Ultra-fine short hair finishing, ultra-fine long hair finishing; newly developed processes |

| Surface layer | General polyurethane emulsion layer, polymer emulsion layer with moisture permeability and air permeability: newly developed processes |

| Manufacturing process | CATS=CLARINO ADVANCED TECHNOLOGY SYSTEMS (An innovative process developed from directly specialized spinning machine for nonwoven fabrics) |

3. Patent Applications

39 in Japan, 11 overseas

4. Applications

In addition to use in car seats, interior (upholstery), sports shoes and schoolbags, Kuraray will develop a wide range of new applications, including for IT-related specialized materials.

5. Business Development

| Sales Brand | To be developed under the TIRRENINA brand |

|---|---|

| Sales Launch | June 2006 |

| Sales Price | ¥2,500 - 7,000 / m² |

| Sales Targets | First year: 500,000 m² Three years later: 3 million m² |